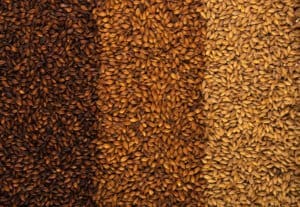

You can’t make beer without malt. While there’s a lot of focus on hops used in the production process, it’s the malting process that adds color, flavor, and sweetness to the beer. Barley seeds are soaked and drained to get the germination process of the seed started. When it germinates, it activates enzymes to convert its starch reserves and proteins into sugars and amino acids. The grain is then dried in a kiln to trap the enzymes until the brewer is ready to reactivate and use the grains. These sugars are used to feed the yeast during fermentation, resulting in carbonation, alcohol, and additional flavors.

Base Beer Malts

Base malts are the foundation for whatever type of beer the brewer is producing. They are selected because they have the highest power to convert starches into sugars and will create the underlying flavor of the beverage. A brewer may combine the base malt with many other types of malts to perfect a specific flavor. Some common types of base malts include:

- Barley malts like pale, Pilsner, Vienna, Munich, and mild ale,

- Non-barley base malts like wheat and rye malts, and

- High-temperature kilned varieties like Munich and Vienna malts.

Once a base is selected, other malts are added to impact the beer’s taste. It’s possible for a brewer to use 7 to 8 different malts in one recipe.

Caramel (or Crystal) Malts

Caramel malts are produced by drying the germinated barley at a specific temperature that will cause the sugars to caramelize. Brewers experiment with the roasting temperature to impact the sweet, caramel flavor of the malt. These will create tastes like caramel, apricot, raisin, fig, and prune flavors. Along with taste, caramel malts also give the beer a smoother mouth feel and better foam stability.

Kilned and Toasted Malts

These malts are heated to a much higher temperature to stop the enzyme process. They will give the beer a toasted or sometimes burnt flavor and dark brown or black color. The taste will be more biscuit, cookie, or coffee-like.

Roasted Malts

These are also heated to a high temperature, but they have a darker, breadier flavor. Some of the most popular varieties are black, chocolate, and coffee malts. Because they have intense flavor, a very small quantity is needed in a brew.

Other Ingredients Used in the Malting Process

There are other types of ingredients that can be used to initiate the fermentation process that are not barley. For example, oats, rye, and wheat can be used. A beer made from malted oats will have a creamy, silky smoothness, while wheat beers have a lighter body and taste.

Explore beers with different types of malts at The Growler Guys.

Explore the growing variety of beers in one taproom, The Growler Guys. Each location carries the best local varieties, from the palest ales to the darkest stouts, along with ciders and kombucha. Our friendly staff is happy to walk you through the characteristics of every style to help you discover your personal favorites. Take home the beers you love best in a growler to share with family and friends. View our online tap list to learn about the available selections at a location near you.

Reader Interactions